Circular innovation

Circular innovation

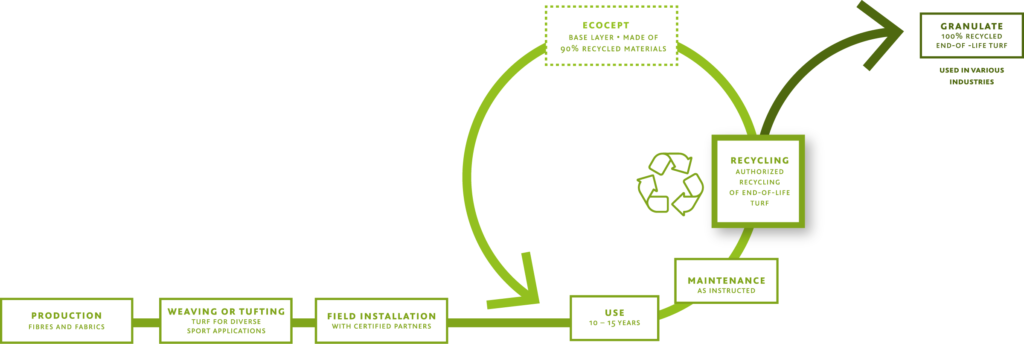

All our innovations are underpinned by our circular design philosophy, a strong commitment to creating solutions that are fully circular and have a sustainability benefit during the use phase. Our goal is to have a circular portfolio by 2030, without compromising on quality and performance. Some results of this approach so far:

- High-end, top quality non-infill solution for elite-football

- One-DNA turf for landscaping launched in 2022, made from one single polymer

- Products like Geocool, Solteria Max and Ecotherm that help keep surfaces cooler during sizzling summer days

- FIH certified water-free hockey surface, saving up to 3.5 million liters of water per pitch per year

- Natural infills like cork and olive pits

- Products made of recycled materials like Ecocept (baselayer, 90% recycled materials) and Econailer (nailer board, 100% recycled materials).

- Solutions to store water underneath the surface

End-of-life solution for artificial turf

As an industry leader, we have a responsibility to take care of our turf end of life. That’s why we have established several recycling partnerships.

Partnership with GBN

In 2019, we started our first recycling partnership with GBN recycling services. With the aim to offer a solution for all legacy turf in The Netherlands. To date we’ve recycled almost 25 million square feet of turf. The materials produced by GBN are, among others, used as an ingredient for our Ecocept. A baselayer made of 90% recycled content.

We will expand this recycling initiative across Europe and provide an end-of-life solution for all legacy artificial turfwithin the next 5 years. Our aim is to set up a recycling network in Germany, the United Kingdom, France, and Spain.

Partnership with ExxonMobil and Cyclyx

In 2022, we announced our advanced grass recycling pilot with ExxonMobil and Cyclyx. This pilot is a next step in our sustainability journey to offer a truly circular solution for end-of-life turf in the United States.

During the program, 50 aged turf fields from high schools and campuses across the US, are processed. The end-of-life turf will be broken down into raw materials that have the same performance and quality as virgin raw materials. This means that our end-of-life turf can be reused to produce high-quality and high-performance products. After this initial phase is complete, we plan to expand the initiative.

Eric van Roekel CEO GBN Group

“The only way to solve the recycling challenge is by working together.”